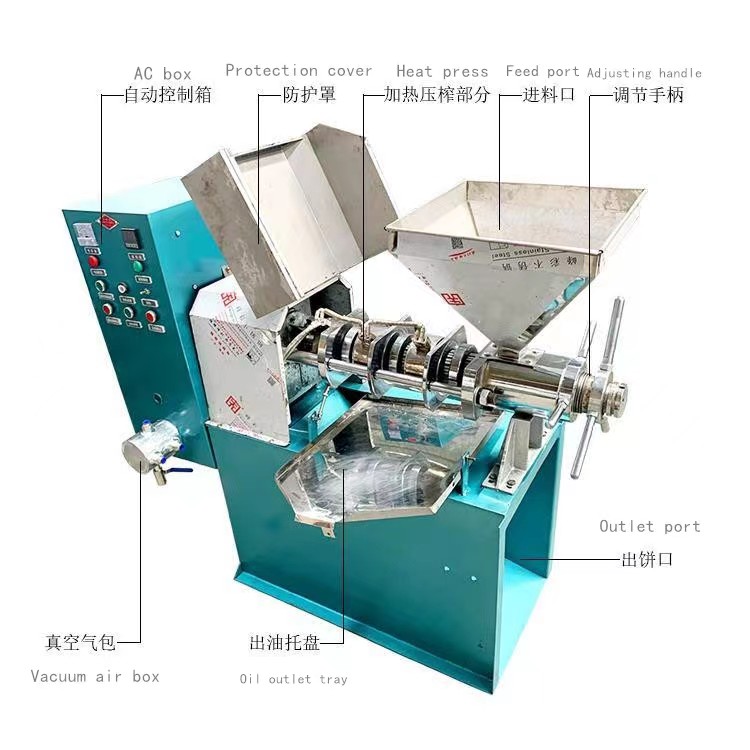

Automatic spiral oil press, with vacuum filtration, automatic temperature control function. The product oil is of good quality. Taste is fragrant, and the oil yield rate is also high. It is mainly used for processing in rural areas. Or in the city to do on-site processing, so that the production loo

CONTACT

Automatic spiral oil press, with vacuum filtration, automatic temperature control function. The product oil is of good quality. Taste is fragrant, and the oil yield rate is also high. It is mainly used for processing in rural areas. Or in the city to do on-site processing, so that the production looks more transparent, so that customers are more assured. It has great benefits to start the business. Many regions operate under this model, and the profits are quite rich. Almost all oil crops can be pressed by an oil press. Including peanuts, soybeans, oil sunflower, rapeseed, walnuts, cottonseed, etc.

Operational principle: When the oil press runs, the processed oil enters the pressing chamber from the hopper. From the spiral to the material embryo continue to push in, pressing. Because the material embryo is carried out in the press of the oil press under the motion state, under the condition of high pressure, the material embryo produces a great friction resistance between the screw, the material embryo and the press, which can make the friction between the material embryo, resulting in relative movement. On the other hand, because the diameter of the root garden of the screw is gradually thickened, the pitch is gradually reduced, so when the screw rotates, the thread can push forward and turn outward. At the same time, the material layer close to the surface of the screw thread also rotates with the pressing axis. In this way, each material embryo particle in the chamber is not at equal speed and moves in the same direction, but there is a relative movement between the particles. The heat generated by friction and meet the necessary oil process on the operation of heat, helps to promote material embryo protein heat denaturation, destroyed the colloid, increase the plasticity, but also reduces some viscosity easy to precipitate oil, thus improving the oil press rate, make the oil in the material, and from the garden cracks and row gaps.

Technical parameter:

Type | FL-60 | FL-70 | FL-80 | FL-100 | FL-120 | FL-130 | FL-150 |

Dia. | φ 53mm | φ 68mm | φ 80mm | φ 100mm | φ 120mm | φ 130mm | φ 150mm |

Speed | 64r/min | 64r/min | 63r/min | 43r/min | 37r/min | 36r/min | 33r/min |

Host power | 2.2KW | 3KW | 5.5KW | 7.5KW | 11KW | 15KW | 15KW |

Vacuum pump | 0.37KW | 0.55KW | 0.75KW | 0.75KW | 0.75KW | 0.80KW | 1.1KW |

Heater | 0.9KW | 1.8KW | 2.2KW | 3.5KW | 4KW | 4KW | 4KW |

Capacity | 30-50Kg/h | 60-80Kg/h | 80-130Kg/h | 140-220Kg/h | 250-350Kg/h | 300-450Kg/h | 450-550Kg/h |

Weight | 230Kg | 280Kg | 830Kg | 1150Kg | 1500Kg | 1800Kg | 1950Kg |

Size | 1200×800×1150mm | 1450×870×1180mm | 1500×1200×1750 | 1700×1300×1850 | 2000×1300×1500 | 2100×1300×1600 | 2380×1680×2000 |

Circle dia. | 63 | 83 | 83 | 98mm | |||

Voltage | 2 phase 220V | 2 phase 220V | 3 phase 380V | 3 phase 380V | 3 phase 380V | 3 phase 380V | 3 phase 380V |

Dry cake residual oil rate | 6% | 6% | 6% | 6-8% | 6-8% | 6-8% | 6-8% |

Oil rate | 45% | 45% | 45% | 55% | 48% | 46% | 50% |

Product superiority:

High oil yield--using the principle of multi-stage propulsion and gradual pressure, making the oil fission separation, and then using infrared temperature control system, automatically control the pressing temperature and water, so that the direct softening of the oil to activate the oil molecules, pressing stability, one extraction, greatly improve the oil yield.

Energy saving--the same output reduces the electric power by 40%, with the average saving of 6 kilowatt-hour, daily production can save 30 yuan of electricity.

Provincial workers--the same output can save 60% of the labor force, 1 to 2 people can organize the production, can save the labor effect of about 40 yuan per day.

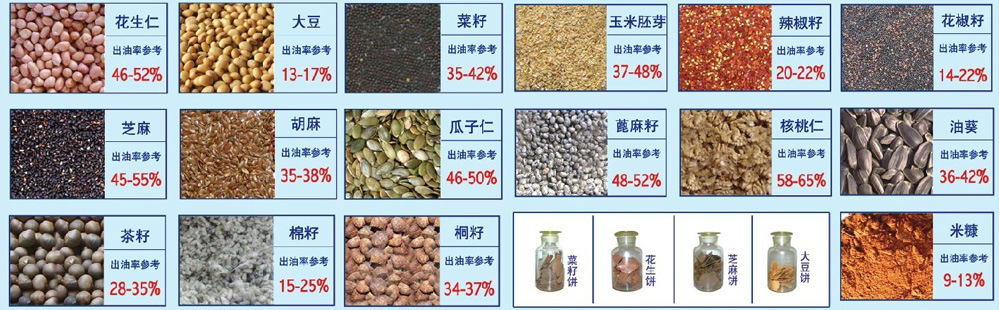

Wide use--a multi-purpose machine, can press peanuts, soybean, rapeseed, sesame, oil sunflower, sesame seed, camellia seed, cottonseed, pepper seed, walnut seed, tung seed, castor bean, almond and other more than 30 kinds of oil crops. Multistage press, one squeeze net.

Pure oil--vacuum filtration residue, to ensure oil purity, in line with health and quarantine standards. Covering a small--oil workshop needs 10-20 square meters to meet the use.

Novel conception, electromechanical integration Scientific design, reasonable structure, simple operation, safe and stable, the use of full automatic device, from the projection to the finished product a complete only a few minutes.

Excellent material, precise technology Using high carbon steel, through high frequency quenching, heat resistance treatment, high hardness, high strength, good wear resistance, adapt to high temperature and high pressure continuous operation, improve the service life of the oil press, the use time can reach several decades.