It is suitable for drying seafood, vegetable dehydration, tremella, melon seeds, peanuts, fruits and vegetables, meat products, casing, tobacco leaves, leather, mushroom, barbary wolfberry, dried fruit, cloth, bamboo shoots, sludge, etc.

CONTACT

It is suitable for drying seafood, vegetable dehydration, tremella, melon seeds, peanuts, fruits and vegetables, meat products, casing, tobacco leaves, leather, mushroom, barbary wolfberry, dried fruit, cloth, bamboo shoots, sludge, etc.

It can realize the low temperature air closed circulation drying, which can avoid the impurity contamination caused by the exchange with the external gas, which is especially important for food, medicine or biological products, and the material drying quality is good. Through the working condition of the control device, the temperature of the hot dry air in the dry room is between 18~80℃, can meet most thermal material high quality drying requirements; the drying medium in the heat pump drying device in the closed circulation, no material dust, volatile substances and odor discharged to the environment; the exhaust gas in the dry room is directly recovered by the heat pump to heat the cold dry air, without the heat pollution of the unit to the environment.

Heat pump drying device SMER (water component in the wet material removed by unit energy consumption) is usually 1.0~4.0kg/kWh, compared with ordinary drying device (air temperature> 40℃), because the heat pump dryer initial investment is generally higher than air electric heating device, gas or coal heating furnace, so the initial investment of drying device is generally higher than ordinary drying device, heat pump dryer drying device energy efficiency is high, low operating cost, its comprehensive economy has certain advantages.

Features:

1、 The closed heating dehumidification cycle drying mode is adopted to save the operation cost, no waste gas, waste heat emission and no noise

2、 It can be dried at low, medium and high temperature (18 ~ 80 ℃), with good quality, high grade and no pollution.

3、 In the drying process, the material is not deformation, not cracking, not changing color, not deterioration, not oxidation, dry thoroughly, good rewater after drying, less loss of nutrients, long storage period, more effective than any traditional drying equipment to protect the color, fragrance, taste, individual form and effective ingredients of drying material.

4、 Easy to maintain and operate and prolong the service life of the equipment;

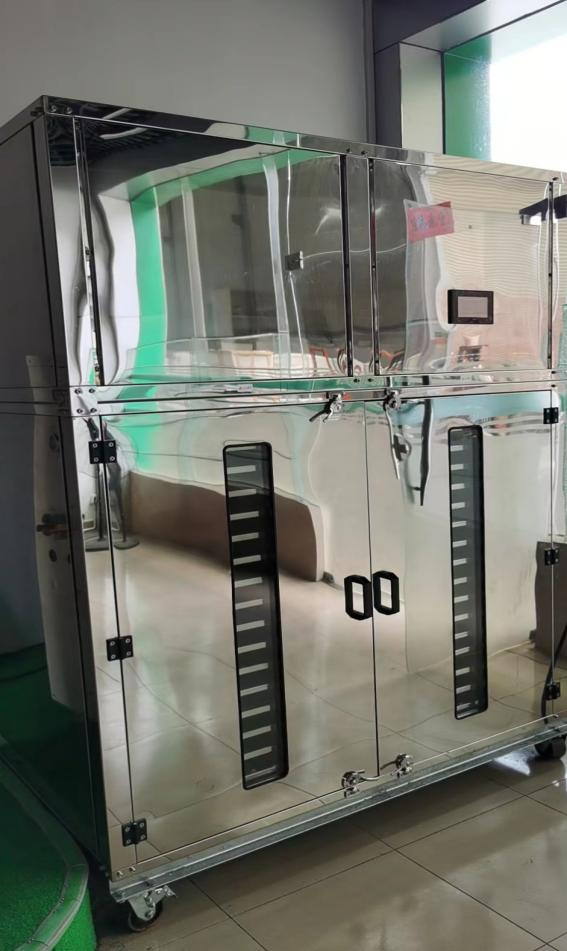

Main Parameter:

Power | Voltage | Capacity | Device | Drying temp. | Drying duration | Size(mm) | Remark |

1.5P | 50-100kg | 4-8 h | 1270*760*1850 | Power and size can be customized according to customer requirements. | |||

3P | 380V50Hz | 300kg | Pallet/shelves | 28-110°C | 10-15h | 1600*860*2030 | |

7P | 380V50Hz | 500kg | Pallet/shelves | 28-110°C | 12-16h | 6000*2100*2400 | |

10P | 380V50Hz | 1000kg | Pallet/shelves | 28-110°C | 16-20h | 6800*2300*2800 | |

12P | 380V50Hz | 2000kg | Pallet/shelves | 28-110°C | 18-24h | 7000*3200*2880 | |

15P | 380V50Hz | 4000kg | Pallet/shelves | 28-110°C | 20-40h | 8600*3500*3000 | |